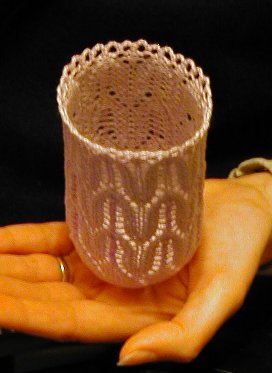

… though it looks more like a vase. It will, of course, soften up once it is handled. Now to make a drawstring for it.

Well, that was my answer, and the question was how to block a knitted lace bag that is a small cylinder with a curved bottom. I couldn’t just pin it out like a doily, but it definitely needed blocking. The soy sauce bottle was the closest I could find to the right diameter, the lump of clay gave the curved bottom, and wrapping them in plastic kept the bag clean. Next problem was that the crochet loop edging needed stretching too, so I looped some cotton warp yarn through the thread I’d already run though the crochet loops, through a loop tied around the neck of the bottle, back through the thread and so on, then once it was all in place, I tensioned it carefully. Since that description is probably clear as mud, here is a pop-up picture.

… so I thought I’d better put something up tonight. I’ve been working on a bag for another small bag exchange. I decided to knit rather than weave this time – knitted cotton lace, of course. I’m using 10/3 crochet cotton on 1.75 mm (US #00) needles. It looked a bit dull so I added some beads. The bottom is a standard ‘swirly’ doily centre with a few decreases to make it ‘cup’ rather than lie flat. Then I switched to Arrow Lace (from one of Barbara Walker’s Treasuries), adding a few seed beads to accent the pattern. I’ve finished the beading (unless I decide to add some to the border) but I haven’t decided where to go from here, except that I’m going to need eyelets for a drawstring. I’ll think about that tomorrow. The scan isn’t very good – the lace needs stretching and the beads don’t show up, so I needed to include a detail scan.

Well, here are the results of a week’s dyeing:

The skeins in the middle row are the ones for the actual sample warps, along with some commercially dyed yarn (not shown). There are 153 skeins in all, ranging from 10 yds to 200 yds each. The yarns are a 6/2 weaving cotton and a 10/3 crochet cotton in white and various starting colours and a 5/2 unbleached weaving cotton.

I used a total of about 70 dye combinations, using Procion MX dyes and the ‘polythene bag’ method. For this, the skeins were dipped into a small amount of the dye mixture, not even enough to cover them, and squidged around to push the dye through the skein. The dye was then squeezed out and the skeins put into a polythene bag to sit for at least an hour before rinsing out and washing in the washing machine, then drying in a tumble drier. At first, we were putting the skeins into pillow cases and net lingerie bags for the washing and drying, but we found that we could put the loose skeins into the dryer without tangling problems, and that speeded up the drying.

The source pictures (cut from magazines) which I am using as inspiration are these purple flowers, which I think may be encased in ice, and this seascape. Originally, I was trying to use these leaves, with or without the rose, but as you can see, my attempts at subtle grey-greens kept turning out sludgy olives, so I turned back to the seascape. I’m more likely to base a real project on the purple flowers, though.

[You need to close the pop-up window between pictures, or it shows them all in the same size window, which crops some of them.]

DH’s sources (much brighter than mine) are these orange wallflowers(?) and purple tulips and this underwater scene.

Oh, I’ve just realised I haven’t mentioned that the tutor was Janet Phillips and it was her Colour in Fabrics workshop. I’ll post pics of the sample warps eventually.

I’ve been busy dyeing sample skeins of cotton. I am trying to match the colours in some source pictures. Once I get them right, I’ll be dyeing the warps for a weaving design workshop. The only(?) problem is that the workshop is on Saturday and I’m still at the sampling stage. If the ones currently ‘cooking’ fill the last few gaps, I’ll dye the actual warps tomorrow and Rys and I will warp up both table looms on Friday. Wish me (no, us) luck!!!!

Anyway, this morning I had a lovely surprise when a small padded envelope dropped through the letter box, and inside were …

They were handknitted for me by the wonderful Gina, who used to host this blog on her site. they are less than 2″ top to toe. I don’ tknow whether the yarn was handspun and/or home-dyed but neither would surprise me.

Aren’t I lucky?!?

I’ve finished the first end of the EG. The pattern says to start with a waste yarn cast on, knit the middle section and one tail, then pick up the open cast on stitches and knit the last tail. As I have barely enough yarn and I want to make the scarf as long as possible, I wanted to know exactly how much yarn a tail needs (10.1 g, it turns out) so I can continue with centre until I have just enough left for the second tail. I took a picture of the first tail before picking up the cast on. It’s pinned out but not stretched for proper blocking.

I showed my mother the yarn I dyed for ‘her’ EG scarf, though she doesn’t know that yet, and she loves it. Phew! Here it is:

I’m currently knitting a new swatch as the dyed yarn will probably not match the gauge of the undyed swatch. With luck, I’ll get to start the scarf itself tomorrow.

Here is a picture of the (almost-)dry bowl, with the colours looking closer to the real colours, and one of the yarn I used.

The next question is “Is it finished?” I rather like its simplicity, and the surface texture does add interest, but I’m wondering whether the swap recipient might be disappointed if I don’t embellish it at least a little. I think I’m going to try to make a couple more bowls before the swap deadline anyway, so if I do I’ll make those a little fancier. Pictures to follow when/if I make them. :-)

Since I last posted, I’ve been working on a knitted-then-felted bowl for an exchange on one of my lists. I’ve never intentionally felted knitting before. I made small swatches using various commercial merino yarns, and even knitting with merino roving, but I didn’t like the way they turned out.

In desperation, I tried some thick 2-ply handspun merino from a few years ago. I only had 65 yards of it, but I thought that might be enough for a swatch and a bowl. That swatch looked a lot better so I went ahead with the bowl. I knitted it like a round garter stitch dishcloth with short row wedges (here is an example of what I mean), but on the outside, I did a similar number of stitches of stockinette with no shortrowing, so that section gets forced up to become the side of the bowl and another 3 stitches for an I-cord edging to make the rim. The I-cord pulls in the rim, which I hoped would make a nice shape, and I think it has worked.

Here is the bowl before felting:

and stuffed with newspaper to show the shape better (it was too floppy to stand on its own at this stage):

and here is one after the first run through the washing machine:

It needed a second run to get it firm enough. By the time it came out the second time, it had shrunk from the original 6″ across the base section by 3″ high to 4.5″ by 2″. It’s not dry yet, so I’ll try to remember to post the final pictures tomorrow, along with the yarn I’ve dyed for the EG scarf/wrap.

Not a lot of news today. I want to check out my Zephyr yarn to see if I have enough of any suitable colour for the EG, but after a long and dangerous expedition into the depths of my stash, the box seems to have disappeared. Now I know I wouldn’t have thrown Zephyr out or given it away, so it must be there somewhere, but I’ve given up searching for the moment.

The good news is I do have pictures of my chair wheel at last. I’ve replaced the one in yesterday’s entry. I’m putting the rest up on my web site as soon as I upload this. Click here to see them.